Wire EDM

EDM Technologies has specialized in wire EDM machining since 1988. Since then we’ve grown to become the largest wire EDM job shop in the southeast.

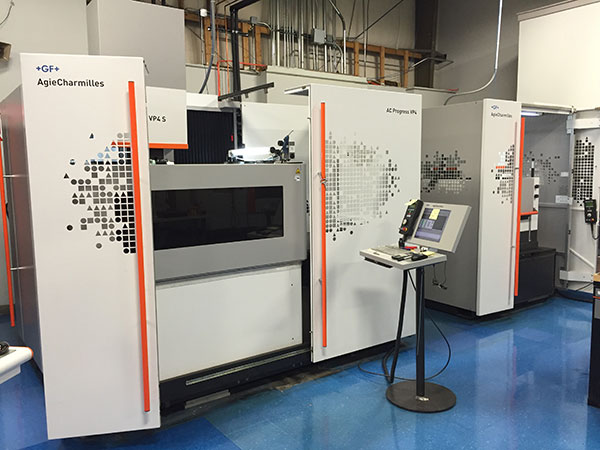

EDM Technologies has the wire EDM capacity to meet your largest production needs, especially those that would overwhelm the capacity of the average size shop.

Wire EDM—also known as wire cutting, wire burning, and traveling wire EDM—uses spark erosion to machine or remove material with a traveling wire electrode from any electrically conductive material. The wire electrode usually consists of brass or zinc-coated brass material.

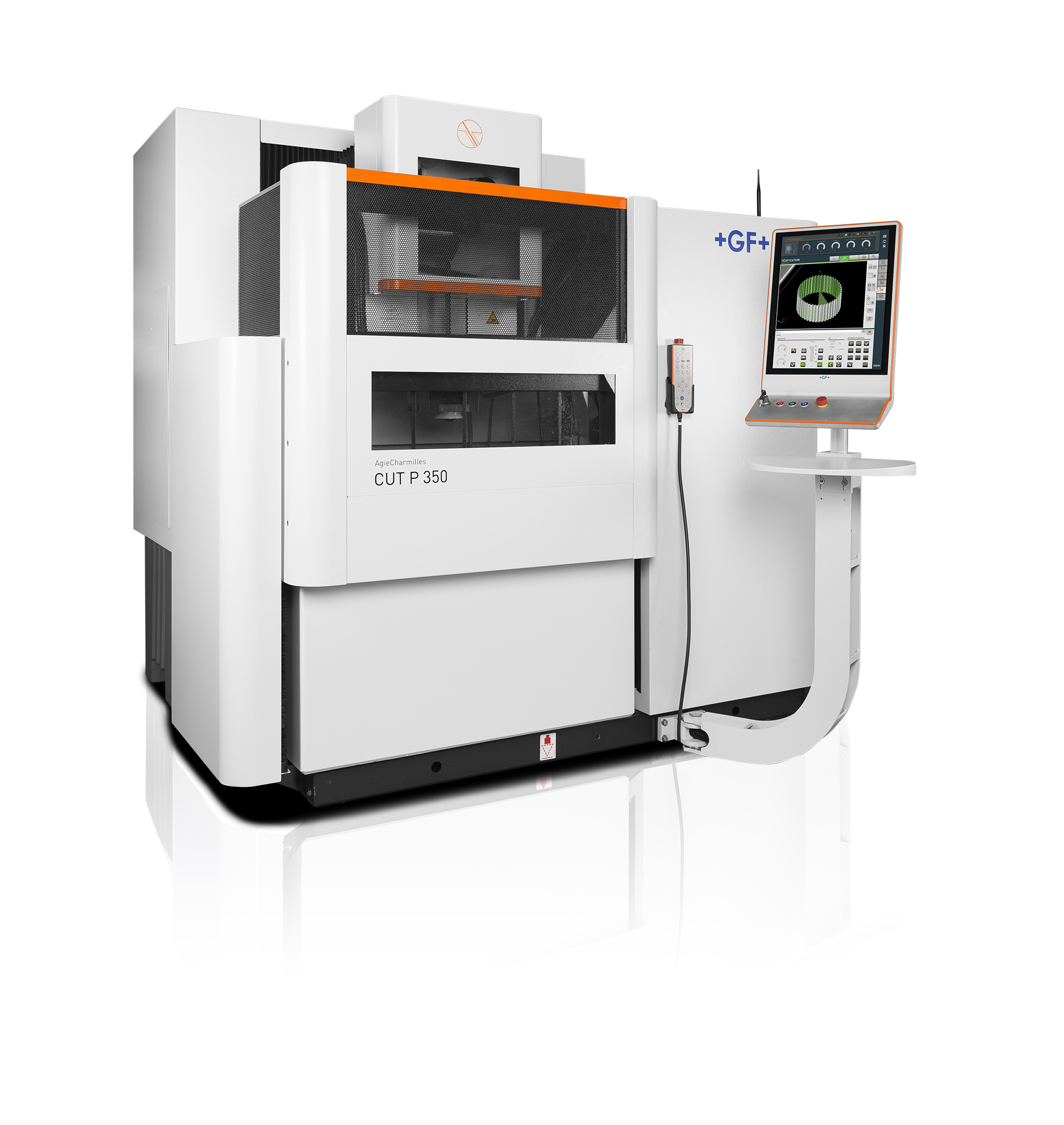

EDM Technologies has 12 high-speed wire EDM machines that are fully automated and operate 24/7. Features of our machines include:

- High-speed wire EDM machines with automatic threading

- Four axis independent UV machining

- Maximum taper angle: 45 degrees

- Maximum cutting height: 20.5″ tall

- Wire diameters from .002″-.010″

- Tolerances can be held to .00007″

- Best wire EDM finish in tool steel/carbide: 4 micro-inch

- Best wire EDM finish in aluminum: 6 micro-inch

- Any conductive material can be wire EDM machined, including aluminum, brass, carbide, copper, hastalloy, inconel, steel, stellite, and titanium.

EDM Technologies uses Esprit 2018 CAM by DP Technology for our wire EDM programming systems. We can accept dxf, dwg, iges, Parasolid, Solidworks, Solid Edge, ProEngineer, and Catia files for easy generation into wire EDM programs.

Whether your application is prototype or high-volume production, no wire EDM job is too small, too large or too complex.